Frame

System Lead: Darren Chen

Darren Chen (dchen61@u.rochester.edu) is a junior, mechanical engineering major from Taipei. This is his third year on the team and second year as frame lead. He previously served as a team member in the shop working on frame manufacturing and design.

Roles and Responsibilities:

The frame team is in charge of designing, testing, and manufacturing the chassis for the vehicle. Siemens NX is used for the design, finite element analysis and simulations of the different stresses on the chassis. In addition, the frame team collaborates with the electronics and instrumentation team to perform physical testing using strain gauges in order to validate the load cases calculated in the design programs.

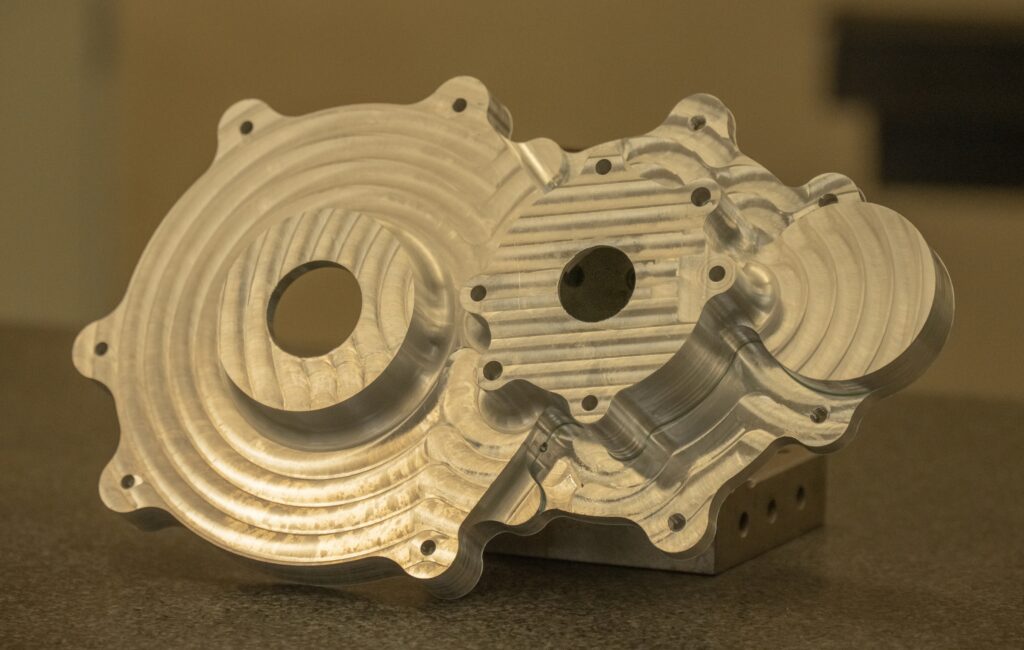

Drivetrain

System Lead: Kaan Aytekin & Arthur Chen

Kaan Aytekin (kaytekin@u.rochester.edu) is a junior Mechanical Engineering major from Istanbul, Turkey. This is his third year on the team and he previously served as the Power Distribution lead. He also serves as the Chief Engineer.

Arthur Chen (achen110@u.rochester.edu) is a junior Chemical Engineering major from Perrysburg, Ohio. This is his third year on the team, and he has previously worked as a team member on the electronics team and as the brakes lead.

Subsystem Leads:

- Power Distribution: Jonathan Wu (jwu140@u.rochester.edu)

Roles and Responsibilities:

The drivetrain team is responsible for powering the car. Typically, our vehicles run a CVT (Continuously Variable Transmission) from the engine to a double stage reduction gearbox attached directly to the wheels. We design and manufacture a new gearbox every year. We are also responsible for tuning the CVT once the car is complete to achieve maximum performance by balancing top speed, torque, and acceleration.

Suspension

System Lead: Natalie Shank & Miles Owen

Natalie Shank (nshank@u.rochester.edu) is a junior Mechanical Engineering major from Chiang Mai, Thailand. This is her second year on the team where she was previously part of the suspension team and a welder. Currently, she is still a part of the welding team.

Miles Owens (mowens13@u.rochester.edu) is a junior Mechanical Engineering major from Orinda, California. This is his third year on the team and the second year as a project team lead where he previously served as the composites team lead.

Subsystem Leads:

- Power Distribution: Jonathan Wu (jwu140@u.rochester.edu)

- Steering: Siena Maislin (smaisli2@u.rochester.edu)

Roles and Responsibilities:

The suspension is all hardware that connects the tires to the chassis, allowing for relative motion between the two. The design of a vehicle’s suspension is the determining factor in its handling characteristics; traits such as turning radius, roll while turning sharply, or response to driving over an obstacle. To design and manufacture the suspension, the suspension project team makes use of a variety of CAD and finite element analysis tools (such as Siemens NX and SolidWorks) as well as manufacturing techniques such as CNC machining, milling, lathing, and welding. Once the suspension has been built and mounted, the suspension team is responsible for tuning the suspension to match our drivers’ preferred handling traits and terrain, as well as being ready to swiftly replace broken parts during a race.

Usability

System Lead: Marcela Hinojosa (mhinojo4@u.rochester.edu)

Subsystem Leads:

- Brakes: Giovanny Marin-Cruz (gmarincr@u.rochester.edu)

- Steering: Siena Maislin (smaisli2@u.rochester.edu)

Roles and Responsibilities:

“Ergonomics” at UR Baja SAE refers to how efficiently we can design the components that relate to the safety of the driver. What do we mean by efficiency? An efficient design should be a workable model that is as weightless as possible, while also being keeping in mind the budget that we are working with, but we are willing to spend as much money as possible it means that we can secure the safety of our drivers.

We, at the Ergonomics Team from UR Baja SAE, focus on the optimization of the various composites that make up the bulk of the driver’s cabin based on the regulations placed by the official SAE Baja organization. We have broken down the Ergonomics Team by three sections: Steering, Brakes and Composites, in order to distribute the workload to realistically meet our deadlines.

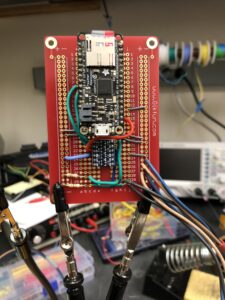

Electronics & Instrumentation

System Lead:

Jacob Weingard (jweinga2@u.rochester.

Roles and Responsibilities:

The Electronics & Instrumentation team is responsible for all electrical systems on the vehicle, and for gathering data which validates the design decisions made for the vehicle, completing the design cycle. Innovating new and exciting ways to validate strain, speed, heat, kinematics, pressure, and everything in between is the name of the game for the Electronics & Instrumentation division.

Subsystem: Power Distribution

Subsystem Lead:

Johanthan Wu (jwu140@u.rochester.edu) is a sophomore Mechanical Engineering major. This is his second year on the team.

Roles and Responsibilities:

The power distribution team focuses on transmitting power from the engine to the wheel hubs. This includes design of halfshafts and their connection methods to the rest of the car. We work closely with the suspension and drivetrain teams to ensure the car is able to accelerate at peak performance without interference with other components.

Subsystem: Steering

Subsystem Lead:

Siena Maislin (smaisli2@u.rochester.edu) is a junior Electrical and Computer Engineering major from Arlington, MA. This is her second year on team where she was previously part of the marketing team.

Roles and Responsibilities:

The steering subsystem includes everything from the steering arm connections on the uprights to the steering wheel. In order to properly optimize this subsystem, many things need to occur. This includes conducting turning radius tests, motion simulations for steering rack mobility, FEA on steering rack supports and more. Key responsibilities include optimizing the turning radius and optimization for driver comfort/ease of use when steering the vehicle.

Subsystem: Brakes

Subsystem Lead:

Giovanny Marin-Cruz (gmarincr@u.rochester.edu) is a sophomore Mechanical Engineering from Brooklyn, New York. This is his second year on the team.

Roles and Responsibilities:

The brakes team is responsible for ensuring that the driver is able to stop the car. A good braking system is a necessity in order to ensure that the driver and any spectators remain safe when the car is driving. We work closely with the ergonomics team to ensure the driver is able to comfortably interact with the braking system.

CAD System Integration

System Lead:

Erick Begishev (ebegishe@u.rochester.edu) is a sophomore Mechanical Engineering major from Penfield, New York. This is his second year on the team.

Roles and Responsibilities:

The system integration team is responsible for ensuring the integrity of the full assembly and the interfaces between systems. This includes using Computer Aided Design (CAD) software, assemblies, and Product Data Management (PMD) systems in order to maintain master assemblies.

Welding

Team Lead: Elizabeth Martin

Elizabeth Martin (emart32@u.rochester.edu) is senior Microbiology major from Windham, New Hampshire. This is her third year on the team, previously serving as a welder.

Additional Welders:

- Natalie Shank (nshank@u.rochester.edu)

- Ella Peddicord (epeddico@u.rochester.edu)

- Weiting Tan (wtan10@u.rochester.edu)

- Angel Bermudez (abermude@u.rochester.edu)

Roles and Responsibilities:

The welding team is responsible for welding all parts of the car, particularly the frame.