By Noah Meyers (Mechanical Engineering, ’20)

The 2018 suspension on the University of Rochester Baja SAE car is currently being designed. While the geometry of the suspension was decided over the summer, some individual parts of this subsystem have never been used before, or have simply been bought stock from another company. This year, we hope to make both a custom rack and pinion assembly for steering, and a custom driveshaft based on two universal joints (u-joints).

Rack and Pinion

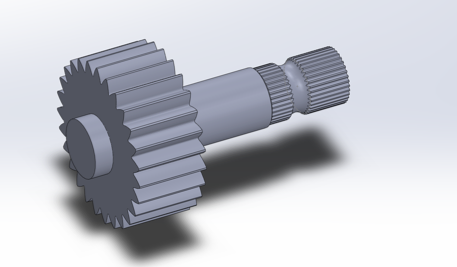

This year our goal was to implement butterfly steering. Butterfly steering means that the driver only has to turn the steering wheel 180º for the steering rack to travel over its entire range. Our current steering rack requires 300º of travel, so to change this, the gear attached to the steering column was made larger.

The next course of action will be to make the housing for both the gear shown and the rack which it turns.

Custom driveshaft

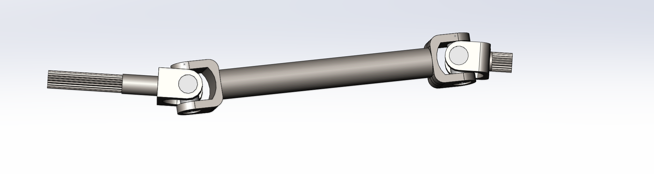

In the recent history of the team, we have used a Polaris CV axle to transfer power from the output shaft to the wheels. Each of these shafts weighs about 8lb, and in an effort to reduce weight this year, we decided to try a different approach for this driveshaft. By modifying the suspension geometry, we can now use universal joints to connect a fixed length shaft to both the hub and the output shaft. Instead of allowing the shaft to change length (this is what a CV axle allows) we now only allow the shaft to travel in and out of the output shaft (the maximum plunge is less than 0.75”, so there is little chance of the shaft slipping out).

There are other smaller projects which will be happening as the year progresses. Some of these are briefly shown below:

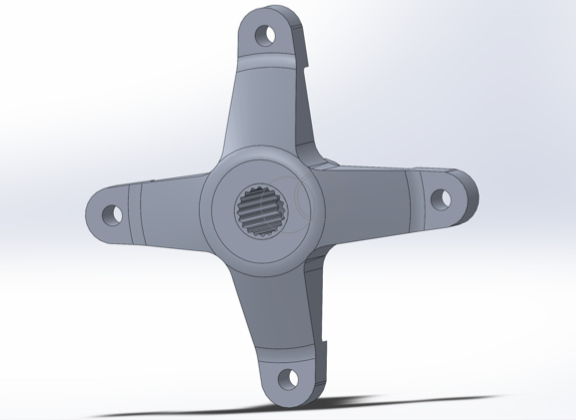

Weight reduction of the hubs

This project is one that I personally worked on last year. The goal for this year is to create a hub from scratch, instead of starting with a hub for a Polaris ATV, and create the part on a CNC machine.

Design of uprights

Arguably the most complicated part of the suspension to design, the process for designing these will begin in a little over a month. They’re designed to reduce weight, while still connecting all other links of the suspension to their correct positions as determined by the suspension geometry.

Roll bar testing

Starting two years ago, the Baja car was fitted with a roll bar. This year’s car will also have a roll bar, however, the exact stiffness of this is yet to be determined. This will be determined through testing on our 2017 car and assessment of driver feedback on various roll bar thicknesses.