By Harel Biggie (Electrical Engineering, ’18)

Below I will outline the recent changes to the electronics team, and the updates we are planning for the 2017 season. I have enjoyed being the electronics team PTL and I look forward to seeing the improvements the electronics team has made implemented on the 2017 car.

Midnight Mayhem

Midnight Mayhem provided an excellent training opportunity for Ian Lawson and An Ho (two new members), to learn about wiring a Baja Car. The 2016-2017 Electronics team is relatively young but the new members are learning quite quickly. Both Ian and An are now fully capable of wiring the kill switches, brake lights, auxiliary lights, and any other components needed for the 2017 car.

At Midnight Mayhem live data was collected for the first time using a Raspberry Pi with an accelerometer. The box was placed on the Rochester Car for the endurance race and recorded data for the entire time the car was in action. The data still needs to be processed but more information about the engine vibrations is needed to do this. We will run static cases on the engine when the Rochester car is reconstructed from the damage at Midnight Mayhem. However, having data from an actual competition is a first for the team and should lead to even more solid designs in the future.

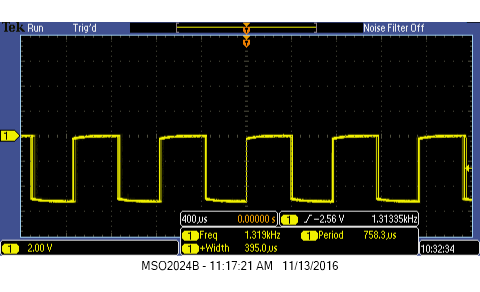

Hall Effect Sensors

Thanks to the work of my predecessor, David Gonzalez, some of the leg work for getting the hall effect sensors up and running was already done. The previous system was capable of recording data at a low resolution of 30 rpm. To improve this resolution, the RPM calculations are now done offline which allows the hall effect sensor to run at its maximum rate. The preliminary results from this change look promising but more testing still needs to be conducted once the Rochester Car is fixed. The system will be ready to go for 2017, allowing us to measure the engine rpm as well as the ratio from the transmission.

Data Collection With Matt Isbell

This year the team was fortunate enough to have one of our alumni, Matt Isbell, return to help with data collection. SimuTech Group, where Matt is employed, is able to provide us with strain gauges and accelerometers. In preliminary trials, it was determined that the engine vibrations need to be dampened in order to obtain more accurate data. The team is looking into accomplishing this for the 2017 car, and that will provide us with more load cases and verification of our designs. Many thanks to Matt and SimuTech Group for all of their help.