Frame

System Lead(s): Benzir Raida

Benzir Raida is a sophomore Mechanical Engineering student from NYC in her 3rd year on the team. She enjoys welding and working on the frames for the team. In her free time, she loves to draw and to play guitar.

Email: braida@u.rochester.edu

Roles and Responsibilities:

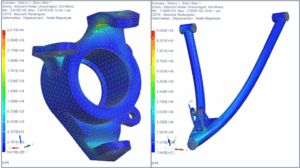

The frame team is in charge of designing, testing, and manufacturing the chassis for the vehicle. Siemens NX is used for the design, finite element analysis and simulations of the different stresses on the chassis. In addition, the frame team collaborates with the electronics and instrumentation team to perform physical testing using strain gauges in order to validate the load cases calculated in the design programs.

Drivetrain

System Lead(s): Jonathan Wu & Ella Young

Jonathan Wu is a junior studying Mechanical Engineering, and has been on the team for 2 years. He previously served as the Power Distribution subsystem lead, and is excited to co-lead Drivetrain with Ella this year! In his free time, he likes hiking and staying active.

Email: jwu140@u.rochester.edu

Ella Young is a sophomore Mechanical Engineering major and aerospace engineering minor from Guilford, CT. This is her 2nd year as a member of the team. She loves manufacturing and fixing the car, but this year she is excited to be a part of the design board and co-lead the Drivetrain subsystem. When she is not in the shop, she enjoys soccer, roller blading, being outside, and playing any instrument she can find.

Email: eyoung35@u.rochester.edu

Roles and Responsibilities:

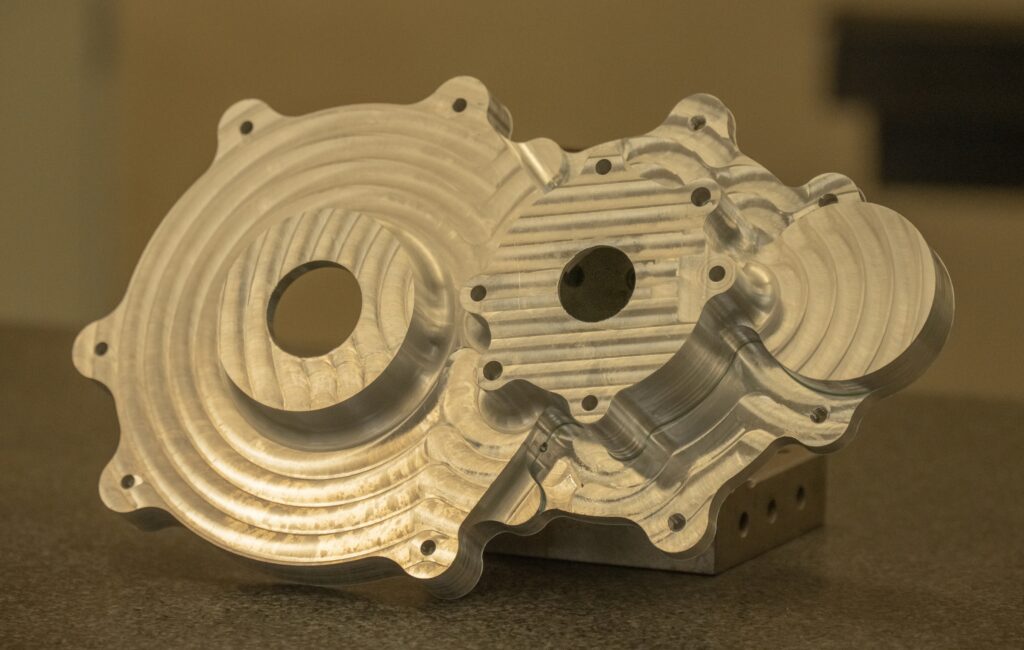

The drivetrain team is responsible for powering the car. As our vehicles can operate in 2WD or 4WD, there are many required components for this subsystem. Typically, our vehicles run a CVT (see Continuously Variable Transmission PTL role) from the Kohler CH440 engine to a double stage reduction gearbox attached directly to the wheels. We design and manufacture a new gearbox every year. For our front drive system, we run an electro-mechanically activated bidirectional overrunning clutch, which performs similarly to a differential. In consideration with our design and manufacturing, we strive to achieve maximum performance by balancing top speed, torque, and acceleration. This requires careful selection of gear ratios, precise manufacturing, and finite element analyses. With a powerful, reliable drivetrain system, our car demonstrates peak performance in competition.

Project Team Lead(s):

Drivetrain: Arthur Chen

Arthur Chen is a senior Chemical Engineering major from Perryburg, Ohio. He has have previously served as the Brakes lead and Drivetrain co-lead.

Email: achen110@u.rochester.edu

Roles and Responsibilities:

The Drivetrain PTL is responsible for maximizing efficiency and coordination of the Drivetrain team. From manufacturing to design, the role allows for flexibility in projects so that when gaps may arise within the team, the Drivetrain PTL is able to fill them.

Power Distribution: Bryce Sabin

Bryce Sabin is a junior Mechanical Engineering major from South Carolina in his 3rd year on the team. He most enjoys manufacturing and learning new techniques, and is excited to lead power distribution on the Baja team this year. He also enjoys playing soccer in my free time.

Email: asabin2@u.rochester.edu

Roles and Responsibilities:

The Power Distribution PTL focuses on transmitting power from the engine to the wheel hubs. This includes the design of half-shafts and their connection methods to the rest of the car. Prioritizing serviceability and manufacturability in our design, we closely collaborate with the suspension and drivetrain teams to ensure the car is able to accelerate at peak performance without interfering with other components.

Continuous Variable Transmission (CVT): Lucas Sabatini

Lucas Sabatini is a sophomore Physics major from the Boston area. This is his 2nd year on Baja. His position involves tuning the CVT which helps keep the engine outputting as efficiently as possible. He loves learning history, fencing, and he has a 1967 VW beetle that he trys to keep running.

Email: lsabatin@u.rochester.edu

Roles and Responsibilities:

The CVT PTL is responsible for tuning and maintaining the Continuously Variable Transmission, which connects the power from the engine to the reduction gearbox. In addition to investigating and developing solutions to tuning the CVT for maximum performance, our team researches and collects data to aid the design of a custom CVT. As the CVT allows for numerous adjustments, we take the car’s abilities, requirements, and the terrain into consideration when selecting the ideal configuration for peak performance.

Suspension

System Lead(s): Miles Owens

Miles is a senior Mechanical Engineering major from Orinda, California. Now in his 4th year on the team, he has previously served as both the Composites Team Lead and the Rear Suspension Team Lead. His favorite part of Baja is CNC machining.

Email: mowens13@u.rochester.edu

Roles and Responsibilities:

The suspension team is responsible for creating a controlled mechanical interface between the vehicle’s frame and its tires. Suspension design is the primary factor influencing a vehicle’s handling characteristics, including turning radius, body roll during cornering, and response to uneven terrain. To develop and manufacture the suspension system, the team employs kinematic line-model simulations (NX Simcenter 3D) and structural analysis using finite element methods in (NX Nastran). These tools support the optimization of key parameters such as ride height, steering geometry, range of motion, and subsystem mass. Fabrication of the suspension components involves a wide range of manufacturing techniques, including CNC machining, manual 3-axis milling, lathe operations, plasma cutting, welding, and more. After installation, the suspension team is responsible for tuning the system to match the drivers’ handling preferences and specific terrain conditions, as well as ensuring rapid repair or replacement of components during endurance events.

Project Team Lead(s):

Steering: Kaelyn Khuat

Kaelyn Khuat is a sophomore Optical Engineering major from Hanoi, Vietnam. This is her second year on the team.

Email: lkhuat@u.rochester.edu

Roles and Responsibilities:

The Steering PTL leads the design and implementation of the vehicle’s steering system. They are responsible for designing and integrating key components such as the rack and pinion, tie rods, and steering column. Working closely with the system Lead, the Steering PTL ensures proper kinematic integration with the suspension system and maintains ergonomic alignment with driver controls.

Brakes: Giovanny Marin-Cruz

Giovanny Marin-Cruz is a junior Mechanical Engineering major from NYC. He enjoys drinking coffee, and is exhilarated to lead brakes on the Baja team this year! He also likes sleeping, rock climbing and listening to music.

Email: gmarincr@u.rochester.edu

Roles and Responsibilities:

The Brakes PTL is responsible for the design, integration, and performance of the vehicle’s braking system. This includes selecting calipers, master cylinders, rotors, and lines that meet safety and performance targets. They collaborate with the Suspension and Drivetrain leads to ensure compatibility across subsystems and oversee the manufacturing, assembly, and testing of the braking system. The Brakes PTL also tunes brake bias and pedal feel to maximize braking responsiveness in Baja SAE dynamic events.

Manufacturing: Cassidy Garibaldo

Cassidy Garibaldo also serves as the New Member Training PTL. See that role for more about her.

Roles and Responsibilities:

The Suspension Manufacturing PTL oversees and supports the fabrication of all suspension components. They work closely with the Suspension System Lead to coordinate manufacturing and testing timelines. This role involves managing processes like CNC machining, manual milling, plasma cutting, and welding, while also supporting iterative testing and vehicle tuning.

Ergonomics

System Lead(s): Miriam Heter

Miriam Heter is a junior Mechanical Engineering major from Stroudsburg, PA. This is her 3rd year on the team. Previously, she served as the Marketing Director. She is excited to take on a new role this year.

Email: mheter@u.rochester.edu

Roles and Responsibilities:

Electronics & Data Acquisition

System Lead(s): Siena Maislin

Siena Maislin is a junior Electrical and Computer Engineering student from Massachusetts in her 3rd year on the team. Last year she served as the Steering subsystem lead and enjoyed designing our steering system. Now as the Electronics and Data Ac. lead, she is excited to use what she has learned in her classes to help build up our testing regimen and bring more electrical engineers to the team. Outside of Baja, she enjoys playing cello, late night drives with friends, and spending as much time outside as possible.

Email: smaisli2@u.rochester.edu

Roles and Responsibilities:

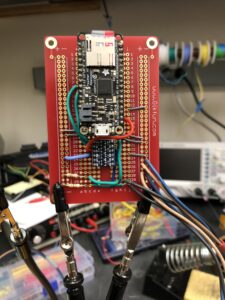

The Electronics and Data Acquisition team has two main responsibilities: The first is to configure all electronics on the vehicle itself (Electronics), which includes the brake light, driver radio, and emergency stop buttons. The second is to design testing setups for other subsystems (Data Acquisition), which is much more creative- finding new ways to measure and record CVT shift curves, component strain, kinematics, temperature, pressure, and more.

Testing and data collection complete the design cycle, enabling our team to further refine our design and improve performance.

Additional Project Team Leads

Computer-Aided Design (CAD) Systems Integration: Erick Begishev

Role Manager: Chief Engineer

Erick Begishev is a junior Mechanical Engineering major from Penfield NY, in his 3rd year on the team and his 2nd year serving as the CAD System Integration lead. He is excited to continue this role and work on our team’s CAD management and integration. Outside of the team, he is passionate about motor sports and spend his free time 3D modeling/printing, working on personal projects involving his computers, bikes, and cars. He also enjoys occasional tennis and commerce.

Email: ebegishe@u.rochester.edu

Roles and Responsibilities:

The CAD Systems Integration PTL is responsible for ensuring the integrity of the full assembly and the interfaces between systems. This includes using Computer Aided Design (CAD) software, assemblies, and Product Data Management (PMD) systems in order to maintain master assemblies.

Analysis and Validation: Kaan Aytekin

Role Manager: Chief Engineer

Kaan Aytekin is a senior Mechanical engineering student from Istanbul, Turkey. This is his 4th year in the team and he has previously served as Chief Engineer, Drivetrain and Power Distribution. In his free time, Kaan likes to play guitar.

Email: kaytekin@u.rochester.edu

Roles and Responsibilities:

The Analysis and Validation PTL is responsible for designing and performing tests to validate simulations. They prepare simulations to validate load cases in and across vehicle subsystems.

Welding Fixtures: Ava Burke

Role Manager: Chief Mechanic

Ava Burke is a sophomore Mechanical Engineering major from Denver, Colorado in her 2nd year on the team. She is excited to to serve as Welding fixture lead on the team this year. In her free time she likes to line dance and work on her truck.

Email: aburke11@u.rochester.edu

Roles and Responsibilities:

The Welding Fixture PTL maximizes the efficiency of welding by using various machines to manufacture fixtures to hold parts together during welding. They work with the design team to ensure their fixtures result in parts that are welded within design tolerances and use their knowledge of welding to ensure that parts have minimal difficulties during welding.

New Member Training: Cass Garibaldo

Role Manager: Chief Mechanic

Cassidy Garibaldo is a junior Biochemistry student in her 3rd year on the team. She enjoys teaching others about Baja, and working on the car before competition. Cass also serves as the Suspension Manufacturing PTL.

Email: cgaribal@u.rochester.edu

Roles and Responsibilities:

The New Member Training PTL is dedicated to uplifting the next generation of Baja members. They host shop tours, training sessions, and small projects throughout the semester to introduce new members to what we do in the shop. They also act as a new member’s mentors, offering guidance for navigating the various offerings of Baja based on their interests.

Welding

Chief Welder: Ella Peddicord

Ella Peddicord is a junior majoring in Mechanical Engineering from Columbus Ohio. This is her 3rd year on the team and 1st year as Chief Welder. She is excited for the opportunity to teach new welders and learn more about the art of welding. Outside of Baja, she is a member of the UR Women’s Rowing Team.

Email: epeddico@u.rochester.edu

Roles and Responsibilities:

The welding team is responsible for welding all parts of the car, particularly the frame.